Machining Processes

Mechanical Processing Facility

- High-end quality products

- Single source for all types of machining and assembly requirements

- 5 axis CNC machining centers up to 30m length and 4,3m width

- Robotic welding lines up to 94m length and 4.3m width

- Dedicated special single production line design for mass production

- Additional services: subcontracting of other parts and accessories based on projects

Expert Partnership

Our clients benefit from a highly skilled technical resource in the ASAŞ Mechanical Processing Team and can expect a consistently high level of professional partnership, focused on efficiently and cost-effectively delivering the best possible prefabrication solution.

Experienced business partner certified with ISO/TS 22163 (IRIS), IATF 16949, DIN EN 15085-2 CL1, ISO 3834-2 quality certificates

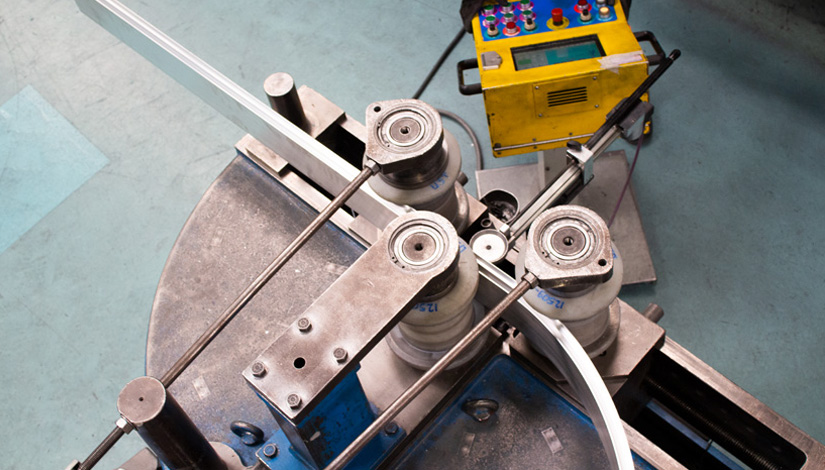

Precision Production

The ASAŞ Mechanical Processing Team provides customers with a world class profile prefabrication solution. Using the very latest prefabrication technology, this team transforms extruded aluminium profiles into high precision components and machined semi-finished or finished parts with internationally certified precision, tolerances and even surface roughness. All cutting and punching tool design is conducted on-site, enabling the ASAŞ Mechanical Processing Team to offer a truly comprehensive range of prefabrication procedures.

Single-Source Benefit

There are many benefits to single-source prefabrication. These include minimizing the number of interfaces required at various stage of supply chain, avoiding unnecessary transportation expenses, reducing scrap, shortening the time between production and application, eliminating the problems that can result from the transfer of profiles between manufacturer and subcontractor and lowering overall production costs.

Further Fabrication:

- 15085-2 CL1 certifi ed TIG and MIG welding

- Dedicated automation for client projects

- Supply of accessories and assembly

- Machining fi xture, tooling and control gauges designing and production

- Anodizing and powder coating

- Assembly

- Kitting and special packing

- Precise CNC cutting

- 5 axis CNC milling

- CNC Tapping

- Punching presses

- CNC and NC bending

Production conditions in line with the industry 4.0 requirements as part of DigitALL (ASAŞ Digital Transformation Project)